In short, CNC machining is a metal fabrication method where written code controls the machinery in the manufacturing process. The code determines everything from the movement of the cutting head and the part to spindle speed, RPMs, etc.

CNC machining services use a subtractive fabrication method. This means that material gets removed during the production process, making it the opposite of additive manufacturing, e.g. 3D printing.

Background

CNC stands for computer numerical control. The evolution towards the current state began with NC, or numerical control only.

The first NC machines were built in the 40s and 50s. These machines were based on existing tools but with some modifications.

Motors moved based on the informational input given to them via punched tape. The code was manually punched into data cards.

In the 50s, the first steps towards CNC machining were done. At first, MIT’s computers were ready to produce the punched tape according to the inputs. In one instance, this reduced the time spent on producing the card from 8 hours to 15 minutes for a milling job.

ARVE error: url: https://www.googleapis.com/youtube/v3/videos?part=snippet%2Cstatistics&id=aDXvyRd3JY4&key=AIzaSyAQ7WFzTAUrOX-FjsIrFS3JwZBFzgIvloc Status code 200 expected but was 403.

Such time-saving capabilities resulted in more R&D work in the field. Soon the first programming languages for CNC machining became available. Over time, largely because of decreasing computer prices, CNC took over the reins from NC.

How Do CNC Machines Work?

Contemporary CNC machines are fully automated. All they need is digital files with instructions about cutting trajectories and tooling.

Design or machining processes require many tools to produce a certain part. Machinists can build digital tool libraries that interface with the physical machine. Such machinery can automatically switch tooling based on digital instructions, making them manufacturing workhorses.

The CNC machining process starts with designing the parts in CAD software. The 3D model determines the necessary dimensions and properties of the final part.

Some of these programs come in CAD-CAM packages, so the flow can continue in the same programs. Otherwise, CAD models are fed into designated CAM software. If both CAD and CAM are from the same product family, no translation of files is necessary. Otherwise, the CAD files need to be imported.

CAM (computer-aided manufacturing) software prepares the model for the whole fabrication process. First, it checks the model for errors. Then it creates a CNC program to fabricate the physical part.

The program is, in essence, a set of coordinates that guides the cutting head during the manufacturing process.

The third step is choosing the right parameters. These include cutting speed, voltage, RPMs, etc. The configuration depends on the geometry of the part as well as the available machinery and tooling.

Lastly, the software determines the nesting. Nesting means the orientation and placement of parts relative to raw material. The purpose is to maximise material usage.

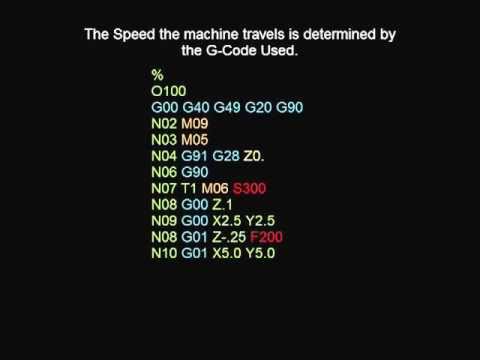

All this information is then translated into codes that the machinery can understand – M-code and G-code.

G-Code vs M-Code

ARVE error: url: https://www.googleapis.com/youtube/v3/videos?part=snippet%2Cstatistics&id=r5bimWKeMbY&key=AIzaSyAQ7WFzTAUrOX-FjsIrFS3JwZBFzgIvloc Status code 200 expected but was 403.

A common misconception is that G-code is all you need for running machining operations. However, this is not true, as the code can be separated into the two codes mentioned above.

G-code refers to a language that is used to tell a machine how to move. Basically, it is the geometric code. G-code determines the movement and speed of cutting heads.

The instructions are fed to a machine controller which is just an industrial computer. This, in turn, dictates how the motors should move. And the motors, of course, determine the path to be followed.

The M-code, on the other hand, gives all the info that the G-code overlooks. That’s why it is called either machine code or miscellaneous code.

M-code instructions include information about the use of coolant, tool changes, program stops, etc.

So both are equally important but not the same.

- Personal account manager

- Quality assurance

- Payment terms for companies

- On-time delivery by Fractory

What Is CNC Machining?

So, we now know how CNC machines work. However, not all these machines are used for CNC machining.

We will take a closer look at all the different types of CNC machines that are available a little later. But in a traditional sense, CNC machining refers to only a few of these automated processes. Namely milling, turning, grinding, routing, drilling, etc.

Milling

It is an operation where the cutting tool rotates. When the milling tool comes into contact with the workpiece, it removes chips from it.

Milling operations include:

- End milling

- Chamfer milling

- Face milling

- Drilling, boring, tapping, etc.

It is a very universal fabrication method with great accuracy and tolerances. Milling is suitable for a variety of materials and is also very quick. The ability to manufacture a wide range of complex parts is a great advantage.

The disadvantages include a large amount of waste, the need for a variety of tooling and the high cost of equipment.

Turning

While the two are often called just CNC machining, turning and milling have distinct differences. Turning is pretty much the opposite of milling. This means that instead of the cutting tool, the workpiece is rotating.

CNC turning services are commonly used for producing shafts, for example. The tool is brought against the rotating workpiece to cut off bits of metal, known as chips or swarf. Achieving high accuracy for a suitable type of limits and fits system is possible.

Turning is usable on the outside of a cylinder or on the inside. The latter operation is called boring.

Grinding

CNC grinding machines use a rotating grinding wheel to remove material. The objective is to give a high-precision finish to a metal part.

The achievable surface quality is very high. Therefore, it is used as a finishing operation rather than creating the final piece from raw materials.

Routing

CNC routers are seemingly similar to CNC milling machines. Here also the rotating piece is the cutting head. The main difference lies in the materials suitable for cutting.

Routers are a perfect fit for cutting softer materials (not metals) that do not require very high accuracy. The reason for that is its lesser output power.

At the same time, routers are quicker. Therefore, they can produce the parts in less time.

Drilling

While milling equipment can also produce holes, drills are meant for only that job.

The difference? While milling tools use cutting edges around the cutting head’s periphery, drills use the tip of the tool to produce a hole.

CNC drilling machines are commonly used to automate this job, and provide better accuracy and a more cost-effective solution.

Types of CNC Machines

As said before, CNC machines are not limited to the traditional sense of CNC machining equipment.

CNC is widely used to automate a variety of different fabrication methods. These include:

- Laser cutters

- Plasma cutters

- Waterjet cutters

- Flame cutters

- Press brakes

- Milling machines

- Turning machines

- Routers

- Electrical discharge machines, etc.

All these operations greatly benefit from the automation factor. This reduces the human element in the final quality and enhances the repeatability of processes and accuracy.

The description above about the workings of CNC machines applies to all these methods. When turning to a laser cutting service, for example, the same logic applies – the cutting path is automatically generated.

This process like many others, however, does not need some of the extra information like the change of tooling. Because the same cutting head is suitable for the whole duration of the process.

What Can CNC Machining Make?

Seemingly, CNC machining has no limitations. It is suitable for a wide range of materials, including different types of metal, plastics, foam, composites and wood.

3-axis milling machines can produce most of the more basic geometric shapes. For more complex parts, multi-axis milling centres are available.

ARVE error: url: https://www.googleapis.com/youtube/v3/videos?part=snippet%2Cstatistics&id=Ki_lzw1YdWk&key=AIzaSyAQ7WFzTAUrOX-FjsIrFS3JwZBFzgIvloc Status code 200 expected but was 403.

For example, a 5-axis CNC milling centre can help out. While the more common 3-axis one has 3 linear axes of movement, 5-axis machines can also rotate the cutting head and the machine bed.

This significantly improves flexibility but also increases cost. Even though CNC is a lot quicker, manual machining still has its place in the industry. Especially for low-volume rapid prototyping.

But CNC machining still prevails in the sector when high accuracy is necessary. This is the reason why so many industries take advantage of it, including:

- Aerospace

- Electrical

- Defence

- Mining

- Industrial machinery

- Food & beverage

- Clothing

- Automotive

- Product design, etc.

All in all, CNC machining has cemented its place in the manufacturing sector as a reliable and useful way of producing parts. At the same time, CNC machining costs may often be a little bit higher compared to other fabrication methods.

The machinery itself comes with a high price and is difficult to operate, posing some dangers. Thus, the best you to get machined parts is to turn to a company that has the necessary expertise to assure top-notch quality. Fractory’s wide network of vetted manufacturers can accommodate your needs for both CNC turning and milling.